xushuaida

Leave a messageColor Tinted glass is produced by the float process with the addition of small quantities of metal oxides to color the normal Clear glass mix. This coloration is achieved through adding metal oxides at the smelting stage.

| Product Name | Color Tinted Glass |

| Color | Bronze, Dark Bronze, Euro Grey, Blue Grey, French Green, Dark Green, Ford Blue, Dark Blue, Ocean Blue, Pink, etc. |

| Thickness | 3mm, 4mm, 5mm, 5.5mm, 6mm, 8mm, 10mm and 12mm, etc. |

| Product Size | 1524*2134mm, 1650*2140mm, 2140*3300mm, 2250*3210mm, 2250*3300mm, 2440*3300mm and 2140*3660mm |

| Structure | Solid |

| Application | 1. External use of windows, doors, shopfronts and curtain walls in offices, houses, shops, high-rise buildings, etc. |

| 2. Interior glass screens, partitions, balustrades, etc. | |

| 3. Shop display decorations, lightings, etc. | |

| 4. Furniture, table-tops, etc. |

higher transmittance and it is an indispensable material for the construction industry and optical equipment.

| Product Name | Clear Float glass |

| Color | Clear |

| Thickness | 2mm 3mm 3.2mm 4mm 5mm 6mm 8mm 10mm 12mm 15mm 19mm 22mm,etc |

| Product Size | 1830mmx2440mm / 1650mmx2440mm / 1650mmx2140mm |

| 2140mmx3300mm / 2140mmx3660mm / 2440mmx3660mm etc. | |

| Structure | Solid |

| Application | Window and door, Railings, Shower enclosures, Partition, Furniture, decoration, etc |

About us

The advantages of our glass factory are mainly reflected in the advanced equipment and highly qualified technical personnel. First of all, modern glass factories are generally equipped with highly automated production equipment, such as intelligent furnaces, CNC cutting machines, automatic detection systems, etc., which not only improve production efficiency, but also ensure the stability and consistency of product quality. The introduction of automation equipment reduces human error, reduces production costs, and can quickly respond to market demand and flexibly adjust production plans. Secondly, technical personnel is one of the core competitiveness of glass factories. Factories usually have an experienced technical team, covering glass formulation research and development, process optimization, equipment maintenance and other areas. These technicians not only have a solid theoretical knowledge, but also accumulated a wealth of practical experience, can timely solve the technical problems in production, promote product innovation and technology upgrading. In addition, the factory also organizes regular technical training to ensure that employees have the latest industry technology and operating norms, so as to maintain a leading position in technology. The efficient combination of equipment and technical personnel enables the glass factory to hold an advantage in the fierce market competition, meet the customer's demand for high-quality and diversified glass products, and lay a solid foundation for the sustainable development of the factory.

Application

Packaging material

Wooden box or wooden frame: Often used for large or heavy glass to provide strong support.

Carton or cardboard: suitable for small glass products, the internal need to add cushioning material.

Foam and bubble film: Used to fill gaps and prevent glass collisions.

Corner guard and edge guard: Protect glass edges and corners from breakage.

Moisture-proof material: such as moisture-proof paper or desiccant, to prevent the glass from getting damp.

Packing method

Single piece packaging: Each piece of glass is wrapped with bubble film or foam and then packed into the box.

Multi-layer packaging: multiple pieces of glass are separated by soft pads to prevent friction.

Vertical packaging: The glass is placed vertically to reduce the force, suitable for large-size glass.

Flat packaging: The glass is placed horizontally, suitable for small size or thicker glass.

Reinforcement measure

Steel or plastic tape binding: fixed packaging to prevent loosening.

Caulk: Fill the void with foam or bubble film to prevent the glass from moving.

Anti-slip treatment: Add anti-slip pad at the bottom of the package to prevent sliding during transportation.

Participate in an exhibition

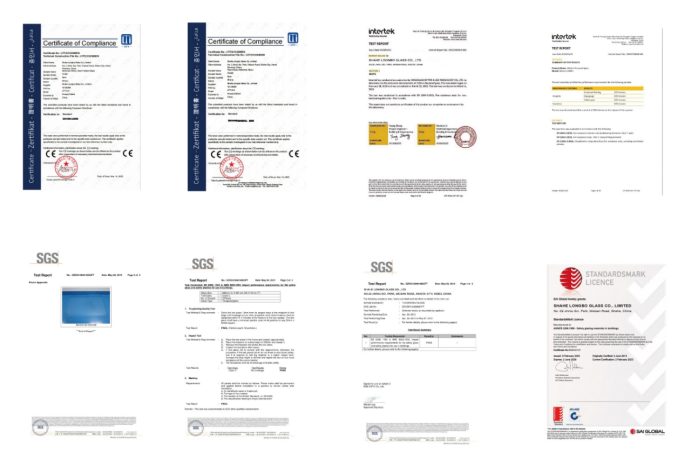

Certificate and qualification

![]()

RELATED

RELATED

Copyright © 2022 Longbo Platform Information Technology Co., Ltd

Back to top

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)